News

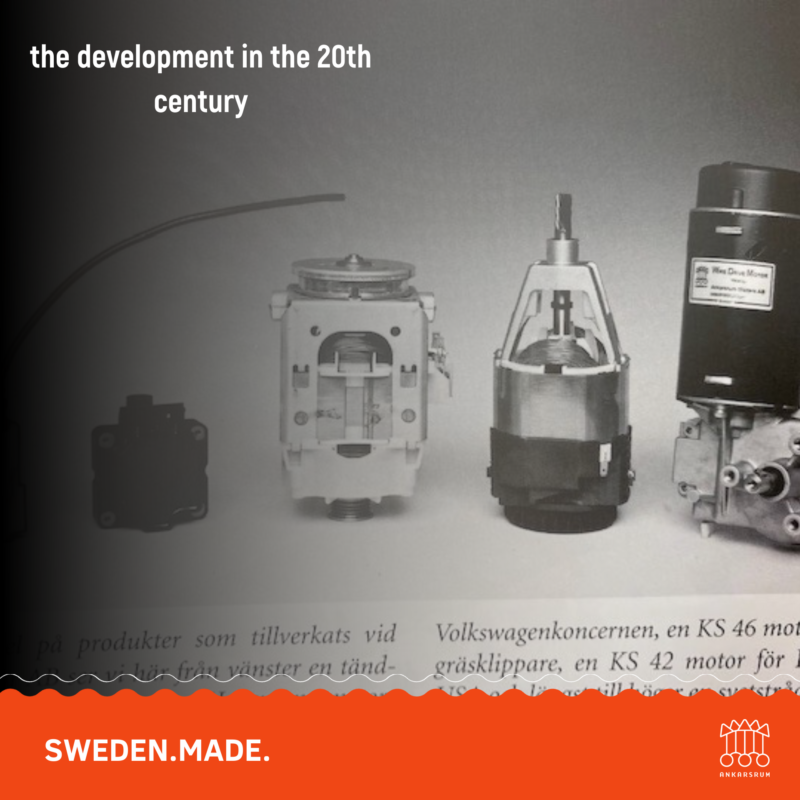

The story of Ankarsrum (part 5) – the development in the late 20th century

In the middle of the 20th century, enamelled cast iron bathtubs were produced at “Bruket” in Ankarsrum among other home appliances products. The production capacity however was limited to only four units per day. Staff members from Ankarsrum were sent to Germany to learn from incumbent companies how to produce more efficiently and the production capacity eventually increased to 30 000 units per year. The CEO, Jonas Spånberg undertook a visit to the Swedish company Gustavsberg that had invested in a new technology which enabled production of bathtubs out of sheet metal. Jonas Spånberg realised that this technology shift would completely change the bath tub industry and decided to divest and pull out of bath tub production.

At the time, the competition for other products intensified and the company lacked funding for developing new products. Therefore, the best option for the Spånberg family appeared to be to make an exit and sell the company. The fast-growing kitchen appliances giant Electrolux had shown interested in acquiring the company, mainly because they wanted to gain control of the new Ankarsrum stove model referred to as Scandinavia. The parties commenced negotiations and Electrolux was represented by the well-known Swedish businessmen Marcus Wallenberg and Hans Werthén. When the acquisition was completed in 1968, a quick sale of several assets followed in Ankarsrum. The acquisition of Ankarsrum became the standard model of Hans Werthén way of consolidating the kitchen appliances industry when Electroclux subsequently bought over 200 competitors, sold the assets and generated good profits from doing so. In 1972, Electrolux sold the Ankarsrum forest assets to the Swedish forest company Holmen.

During the Electrolux period, new products were introduced and mainly comprised electric motors, kitchen machines and die casted components. During the 1990s, windscreen wiper units were manufactured for car brands such as Volvo Saab and Jaguar. Electric motors were manufactured for lawnmowers such as Flymo, ignition systems for VW and chainsaws for brands like Husqvarna. Die casting of zinc and aluminium components were mainly delivered within the Electrolux Group.