News

Ankarsrum has started working with Ansys Motor-Cad from PDSVision

Ansys Motor-Cad is a powerful tool for developing and optimizing electronic motors. We use it today for the development of our new series of inner- and outer runner BLDC-motors (brushless dc-motors).

The biggest advantage of the Ansys Motor-Cad is that we shorten the lead time of new development. Instead of making many iterations and testing of physical prototypes, we make digital simulations to optimize geometry, material selection and parameters as winding data etc. As a final step we do, of course, verify the performance, life length and other requirements in the lab with physical prototypes.

You may think that when the motor is developed, we are done with the Motor-Cad. No, we foresee different applications in many sizes, windings and performance demands. For all these future variants demanded by our customers we will be faster and more precise in development. Faster and more precise also mean less cost.

Steps in working with Ansys Cad:

- Building the geometry in our CAD-system and transfer to Motor-CAD. Add winding data, input drive parameters and material selections.

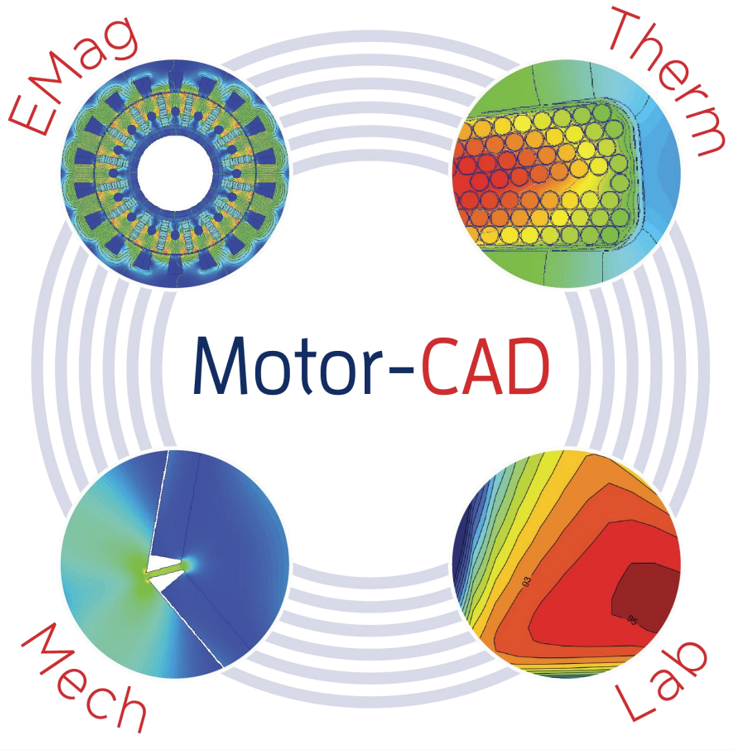

- A model with various aspects will be at hand:

- Emag module for predicting electromagnetic and electric performance.

- Therm module for understanding temperature and optimizing cooling system.

- Mech module for mechanical stress.

- The laboratory module gives much information such as performance, efficiency, analysis of losses including AC winding losses and magnet eddy currents.

With this tool we can change geometry, windings, cooling and get a result within minutes and hours instead of days and weeks. Is it then for anyone to use and succeed? No, you need to have a lot of competence and knowledge in different matters such as materials, electromagnetics, motor development and the tool itself.

Congratulations all customers!